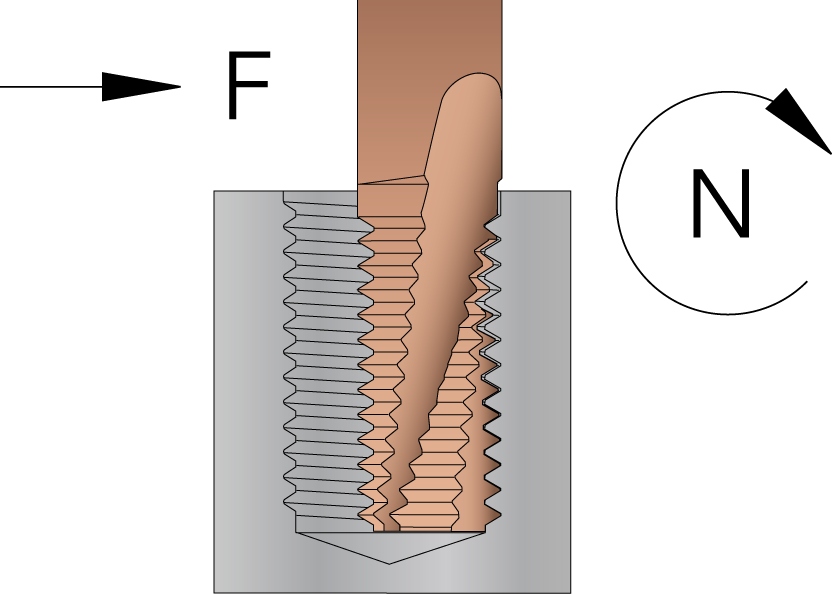

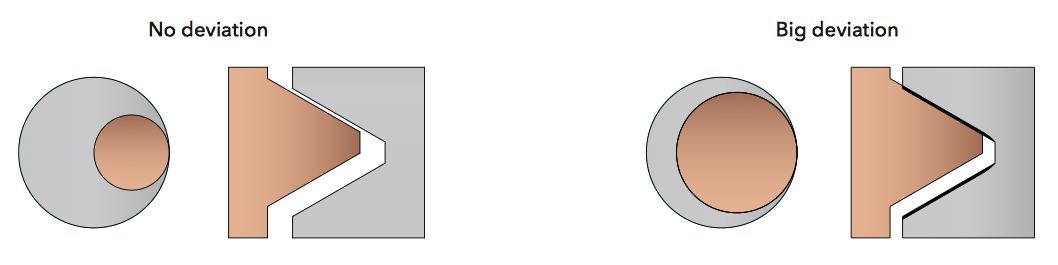

Download PDF When thread milling, the diameter of the tool has to be smaller than the thread diameter. The reason for this is that the thread has a helix angle, but the tool is straight. If the tool is too big there will be a deviation on the thread profile. The size of this deviation depends on several parameters. 1) Thread diameter 2) Cutter diameter 3) Profile angle 4) Pitch Big cutter diameter compared with thread diameter, small profile angle and big pitch. These are parameters that gives bigger deviation. |

||

|

||

There are three alternatives too choose correct thread mill diameter.

Please follow the links to get more information.

|

||

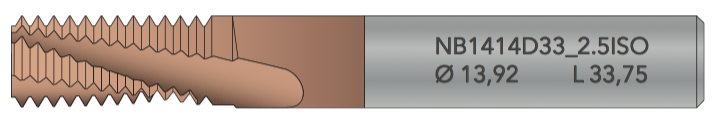

The pitch diameter has become optically measured on thread mills from SmiCut and the theoretical external diameter has been individually laser market on each cutter. This diameter is what you should use in your program to get a correct diameter on your thread. For coarse threads you are normally in the middle of the tolerance if you use the laser marked value. Fine threads may be a little bit tight as you get a very small thread profile deviation on these threads (see above). If this is the case you can mill again after adjusting the diameter in your program. |

||

|

||